High Level Communication

June 07, 2022

In one FIESP publication, citing Abimaq: “While the average age of machines in the manufacturing industry is 4 years in Germany and 7 years in the United States, Brazil's industrial park is already approaching the age of majority: 17 years.”

He also adds that: “Our industrial park is very old, this takes away competitiveness and means underinvestment in machinery.”

It is well known that investment in new machines for the industrial manufacturing process increases productivity and contributes to the technological advancement of the industrial park.

Machine manufacturers are numerous, and can produce machines in series — such as injection molding machines, laser cutting machines — to machines with special features, such as presses or sophisticated cradles. The choice of which depends largely on the operational contexts.

Choosing a software partner for integration with these machines, which are very varied and without a specific standard, is a strategic decision. Strategic because the choice will guide decisions, from the short to the very long term, as it aims to contribute to the perpetuity of the operation.

Here at Sequor, we talk to these machines and, look, they are not few! As time passes, we talk to more and more machines, a number that continues to grow. In these conversations it becomes clear, as we listen to them, that our focus is to help them acquire ever greater quality and robustness of communication, to achieve, in fact, constant optimizations and a positive impact on the transversal effectiveness of our clients.

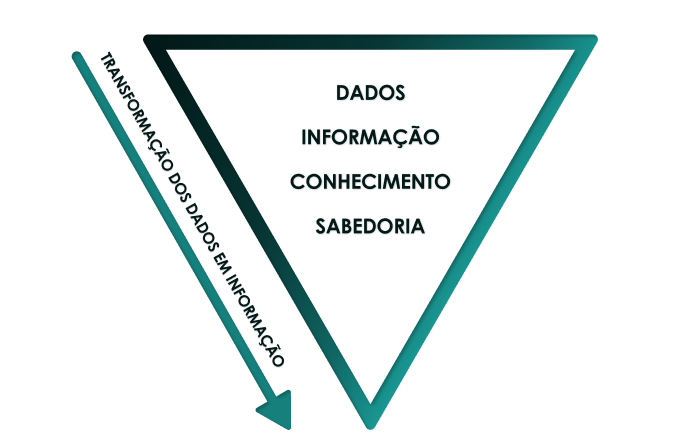

Our knowledge base comes from always choosing to develop a communication driver. Communication drivers are part of the lowest level layer of software, that is, the one whose syntax is furthest from what we know as language and which makes it possible to transform software into content, data, information and, ultimately, wisdom.

We have been developing drivers at Sequor for 17 years.

However, the story begins much earlier: our background dates back to the 90s, with commercial automation, developing drivers for fiscal printers and readers.

In the 2000s, drivers were for servomotors with profibus, serial, modbus protocols and programmable logic controllers for industrial process machines.

Regardless of when, we always develop them with due care to ensure that the data reaches the databases in structured tables. As a result, we were able to eliminate intermediaries and their costs; both those with resources and time.

After all, from a communication point of view, the more intermediaries, the greater the noise in it. This is because whoever controls the intermediaries controls the data. Currently — because of strategic decisions we made in the past — we know how to do this. By talking directly to the machines, we avoid the risk of “wireless telephone” by computing their signals from the source, be they vital, cycle alarm failures or even the health of the machine and production.

EThis, from the market's point of view, is part of our differentiators. Today, he knows that Sequor has the knowledge of how to program the CLP(Programmable Logic Controller) and about the standard IEC61131. And even if we know how to program in ladder, in structured text or in graph set.

For years, we've made machines with static and dynamic measurements, this has further qualified us for machine-level programming: we can take data into banks, structured or unstructured, and present it with an analytical view , contributing to quick and assertive decision-making.

In addition, Sequor has in its portfolio the experience of monitoring in real time more than 100 electronic tightening devices, including Stanley, AtlasCopo and Deprag.

We also created a proprietary visual programming language Logus which currently controls more than 30 manufacturing processes 24x7.

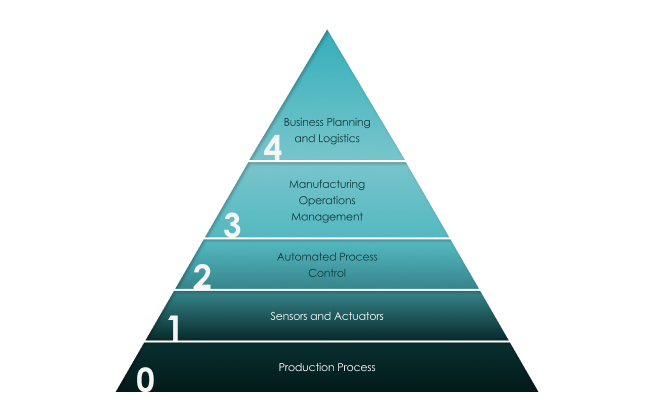

Given the importance of this context, as the base of the systems architecture pyramid is what supports everything that comes above it. Having a well-structured base is one more step for projects and manufacturing process systems to be successful.

For years, we have been studying countless protocols and, thus, accumulating knowledge of how to implement each of them, such as those described below:

We have communication with the following PLC manufacturers already developed

We have communication drivers already developed with the following manufacturers:

And we don't stop there: we know how the types of signals work — digital or analog — and, also, how to put a logic into PWM when necessary, or even a quick count block to catch a cycle, if it is faster than a Relay can capture. In our application and operation engineering we also know how to create an electrical project, obviously qualifying us to read and interpret one.

With all this knowledge acquired, we also chose to create our own variable broker that remotely publishes the data coming directly from the drivers, enabling the entire communication network to view everything that is happening with a certain content, if it has permission to do so.

In short, the application of learnings allows us to quickly assess which types of equipment have or do not have communication, and how to solve both cases since, in real life factories, there are countless machines from countless manufacturers with countless different processes.

Therefore, when choosing a partner, it is important to have the freedom to choose both the software and the hardware, so as not to be forced to limit the use of machinery to a single supplier.

Finally, there is a collective effort to standardize this type of integration communication between machine and software, such as, for example, the OPC protocol. Sequor has been a contributor to the decisions that guide the future of this protocol for more than a decade, as Corporate Members of Opc Foundation.

Thus, we can use everything we know today to allow for a present with machines that are increasingly easier to talk to and have all their intrinsic benefits disseminated.

This site informs: we use cookies to customize ads and improve your site experience. By continuing to browse, you agree with our Privacy Policy..

continue and close